After harvesting large quantities of harvested products, processing needs to be preserved, avoiding damage, causing damage to costs.

Currently, the preservation of agricultural products by cold storage is a priority. The preservation principle of this method is to use low temperature to inhibit the activity of microorganisms, insects, molds … With the lower storage temperature, the more biochemical process occurs on the Agricultural products and limit the development of microorganisms, thus prolonging the preservation of agricultural products longer. Preservation can be enhanced by lowering the temperature further. Temperatures of about 1 degree Celsius at low temperatures can significantly increase the storage capacity.

Mục lục

Storage temperature in cold storage.

The temperature of storage depends on the type of preserved agricultural products and their time. The longer the storage time, the lower the storage temperature.

Farms are divided into the following groups:

– Group fresh fruit: should be stored in a cool store at temperatures from 4-10 degrees Celsius, preservation time lasts from 2-3 days. For some tropical fruits and vegetables, it should be stored at a higher temperature (banana> 10oC, lemon> 4oC). To preserve this food group you need to wrap them in plastic wrap to prevent water loss and the vitamins in the fruit.

Protein food groups include foods derived from animals such as fish, meat, eggs or seafood and plant sources such as tofu, red beans, mushrooms, cereals, etc. This group should be preserved. in a freezer with a temperature of -40 ° C.

Depending on the type of product preserved, the temperature adjustment is appropriate. Note that during storage should keep the temperature stable, not to impact the sudden temperature changes will cause stagnant water, easy to damage the product. When adjusting the temperature rise in one day 1 night should be at 4-5 degrees Celsius. When moving products from the cold store also need through the stage of heat slowly to keep the quality of vegetables.

Humidity of air in cold storage.

It is necessary to choose the humidity of the air in the store suitable for each type of agricultural products because humidity greatly affects the quality of agricultural products when used.

Air velocity in cold storage.

The air in the cold store preserves the heat of preservation products, heat due to opening, due to heat bridges, by workers in storage. Also ensure the temperature uniformity, moisture and mold activity limit.

The benefits of using cold storage

Safe:

Cold storage is a method of preserving a product safe for users.

Maximum storage risk: When stored in a cold store, the product will be kept in an appropriate temperature and humidity environment, dry, cool and hygienic. This environment keeps the product in the best quality, free from deformation and does not create substances that can affect health.

Safety during operation: The equipment is of good quality, stable operation with high longevity so less cause problems during use. In addition, automatic, intelligent control systems can provide timely warning to users.

Saving

Cold storage is the solution to save operating costs. To operate a warehouse, the only cost to spend is on power consumption. However, this cost is not high as all equipment in the system is designed with the ability to optimize power.

Besides, with the usual preservation methods, the product’s storage time is very short so it is easy to cause waste if not timely consumption. Cold storage keeps the product high quality in the long run, minimizing that damage.

Increase sales

Cold storage is the solution to increase sales by reducing production costs and raising product costs. The cold storage as mentioned above is a safer method of storage, which can be stored in large quantities. If divided, the cost of preserving each product will be very low, reducing the overall production price of the product. At the output, the quality assured products should not be devalued. Cold storage also offers the opportunity to transport products away for consumption, even exports to improve the value of products.

In addition, the construction of a storage cold storage will be a stepping stone for long-term development. When you own a cold storage, you will have a solid fulcrum to increase productivity and plan to expand the scale of development.

Cold storage construction

Cold storage is divided into two main sections: insulation and cooling systems.

Insulation system

Insulation systems are parts that play a role in ensuring a stable storage temperature that separates the cold air from the heat exchanger to the outside environment. Cold storage insulation systems include:

1. Storage shelf

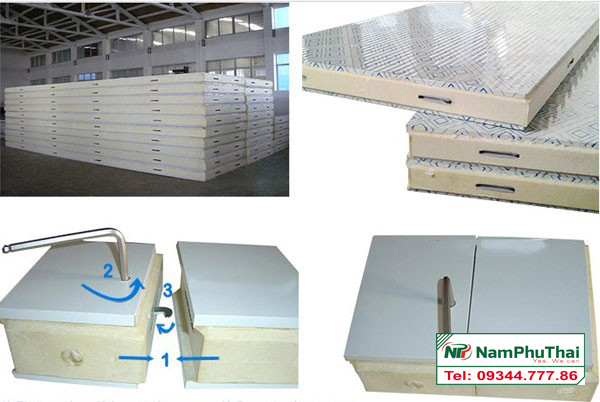

Storage shells are usually made of two types of panel materials, EPS and PU. PU panels are usually used for cold storage and EPS panels are suitable for cool storage.

These two materials have many advantages such as:

Good heat insulation, high durability due to the core is very good heat insulation, preventing cold air escape to the outside.

Sound insulation, heat insulation, anti-cold.

High aesthetics and easy to clean.

Saving time due to the ability to install and move flexible, fast.

Components – characteristics:

Surface Material: Stainless Steel 0.5 – 0.8mm thick;

PVC coated 0.5 – 0.8mm thick;

Color coated sheets 0.5 – 0.8mm thick.

Insulation (PU or EPS) has a density of 38-40 kg / m3, compressive strength 0.2 – 0.29 MPa; Bubble 95%.

Maximum width: 1,200mm

Maximum length: 12,000mm

Standard width: 300, 600, 900, 1200 mm

Standard thicknesses: 50, 75, 100, 125, 150, 175, 200mm

Structure:

Panels are linked together by a camlock or yin-yang. Joints are covered with PU Foam and silicone paste to finish the shell to ensure tight insulation. The panel can be combined with other materials to create decorative blocks.

Other materials used for panel installation:

Uses the keel in a full aluminum exterior, enhances the connectivity and hardness of the panel when assembled

Use two types of Korean hard-imported silicone to apply between the circuit and soft to the outside, prevent heat loss

Other accessories are used according to European standard cold storage

2. Cold storage door

Warehouse doors using Gatter brand products – German standard with two types of doors and sliding doors suitable for all requirements of customers.

Structure:

Two sides coated with stainless steel or tole colorbond, spray PU Foam thickness 75 – 100 – 125 mm.

Joint cold seal

The heating coils are stable, synchronous with the storage operation.

PVC frame is embedded in the wall panel.

Advantages:

Stainless steel or antimony locking hinges & locks with safety lock.

Stainless 304 stainless steel, hinges and handles of atimon or stainless steel material ensure the firmness and shiny of the door.

The structure of the joint around the door, creating air tight when closing the door.

Frame door firmly

Heating resistance makes the door dry and easy to replace.

Cooling system

The role of the cooling system is to adjust the storage temperature to the required level of heat preservation. Therefore, depending on the type of product storage temperature varies, the structure of the refrigeration system is different. Therefore, in the composition only to mention some of the most important equipment in each system.

1. Compressors

Compressor compresses the refrigerant, which is the most important part, the heart of every refrigeration system.

There are many types of compressors such as piston compressors, screws, spiral, … Machines have different structure and operating principles different. Generally, compressors will be imported complete units from abroad. In design and installation based on storage volume and storage temperature to determine the machine capacity used.

In some cold storage units, it is possible to use a condenser compressor instead of using separate equipment to provide better coordination in operation.

2. Indoor unit

Compared with compressors, indoor units are also often imported and there are many brands for you to choose.

The machine model is usually divided into models corresponding to the temperature used in the warehouse.

The indoor unit must be enclosed in a storehouse to ensure a sturdy, aesthetic shell.

Inside the indoor unit there are several important parts that need attention when choosing and using the machine: cold frame, centrifugal fan, defrost resistance, …

3. Control cabinet

The main function of the control panel is to control and regulate the operation of cold storage. With the parameters set up, the regulator will regulate the operation of the equipment so that the temperature is kept constant at the required level.