Frozen storage is the safest way to preserve food, the most cost effective and efficient food, especially the fresh food processing plant, the issue is most important.

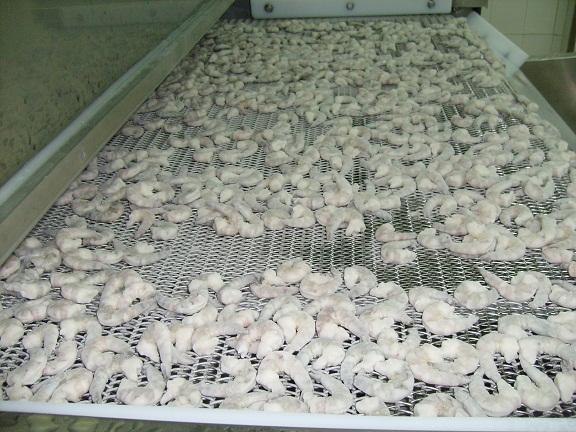

IQF freezing is a method of freezing each individual. The process of placing individual individuals in a temperature range of -40oC to -35oC and after less than 30 minutes, the center temperature of the individual reaches -18oC is called IQF. With the product is frozen IQF, the product storage time is longer but the product quality is almost intact.

Advantages of the IQF freezing method

Fast freezing time

Cost saving operation

The product is not cold, not moving in the machine.

The original shape of the product has not changed.

Industrial hygiene standards are fully met.

Fast, complete block construction, expandable to increase capacity, is available for both NH3 and Freon refrigeration systems.

Products are frozen evenly, less loss, significant savings in power consumption.

Types of IQF refrigeration systems:

Spiral IQF type spiral winding enclosure, also known as Spiral IQF

– Straight type conveyor belt freezers: Straight IQF

– Super-speed conveyor belt: Impingement IQF

In addition, the refrigeration system, the freezing technology, can also be combined with autoclave, cooling, drying, banding and cooling.

Operating principle of refrigeration system, freezing IQF:

The IQF refrigeration system uses NH3 fluid with various types of freezing conveyors and uses a pump-cooled pump.

The IQF refrigerated conveyor belt uses special technology that is located on the conveyor belt, moving at a slow speed, in which it is exposed to cold air and low temperatures.

In the IQF system, the product is moved on a flat plate conveyor using stainless steel material. Thousands of rays and cold air at extremely high speeds blow directly and continuously onto the top of the product and the underside of the conveyor, along with the high thermal conductivity of the conveyor used, quickly refrigerates the product. Two methods are convection heat exchangers and contactors.

Air flow contact around the surface of the product continuously so that the product quickly and evenly surface surface from the beginning of the winter room, thereby reducing the loss of water and loss of products. The quality of finished products has the optimum value for high economic efficiency.

Other IQF refrigerators include: high pressure, low pressure, oil separator, oil recovery tank, intermediate tank, condenser, cooling water pump, drainage pump, slurry and tank slurry

1. IQF refrigerated chillers in the form of twisted pair

The chamber is made of block, two-sided stainless steel wall using 150mm polyurethane material, density 40kg / m3. Conveyor goes in the form of a spring spiral from the bottom up.

Conveyor is arranged with compact chamber, less heat loss, high efficiency. Conveyor belt made of stainless steel or heat-resistant plastic, slow moving by electronic frequency. There is a vibration hammer in the freezer compartment to prevent the sticking of the product and a sanitary drainage system with water and compressed air.

2. Chambers for freezing, freezing IQF freezing system

When a product is deployed on the conveyor belts, blowing cold air onto the conveyor belt surface. Cover polyurethane thickness 150mm, coated with stainless steel. For straight-line conveyors, it’s easy to manufacture, put in and out at two ends. The advantage of this system is the limited heat loss due to the use of a small open system. Besides, this belt has the disadvantage of space because of the large conveyor belt.

Refrigeration chambers freezing, freezing IQF freezing

Similar to the straight level chamber type. However, the refrigerated units in two rows on either side of the conveyor will not consume much space. In addition, the wind tunnel helps cool air from the gas to concentrate more on the product.

The enclosure is covered with polyurethane day insulation 150-200mm on both sides of the stainless steel surface and has cold storage doors with heat-resistant door heating system and also has lights inside.